Packaging is important

Packaging serves several important purposes.

- It correctly labels our food and products.

- It communicates important information to the consumer. Sometimes life-saving information like food allergens and other ingredients. It also helps us know where our food and products come from. This helps if there is a food-borne illness outbreak.

- It protects and keeps our food and products safe.

- It allows food and products to be efficiently boxed in cartons so they ship efficiently. This uses fewer resources, gas, and oil.

- It allows products to be displayed (set, stacked, or hung) in a retail store

Make your packaging sustainable and efficient

Sustainable packaging means that we consider the following when designing packaging:

- What resources are used to make it

- What process is used to make it

- How does it work for the retailer

- How does it works for the customer

- How do we dispose of it

While packaging serves an important purpose, less packaging is better for our Earth. Less packaging means:

- It makes it easier to

- Seldom do you hear a consumer say, “I sure wish this had more packaging to tear through before I can use my product.”

- Packaging should be consumer-friendly. It should be easy to open and reseal if needed.

Less resources and materials are used- The product weighs less, so we use less gas and oil to ship it, we have less damage to our roads and highways that have to be repaired (using more resources, gas, and oil)

Efficient packaging case study

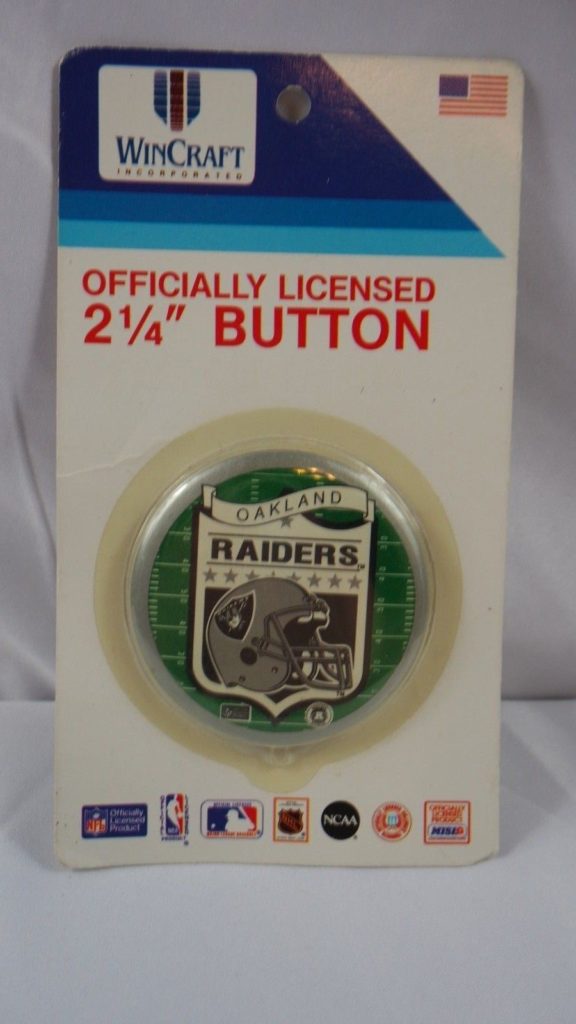

I created this eco-friendly packaging early in my career. At the time, the company I worked for put the sports licensing buttons in a blister pack that was heat sealed to a large header card. It looked like this:

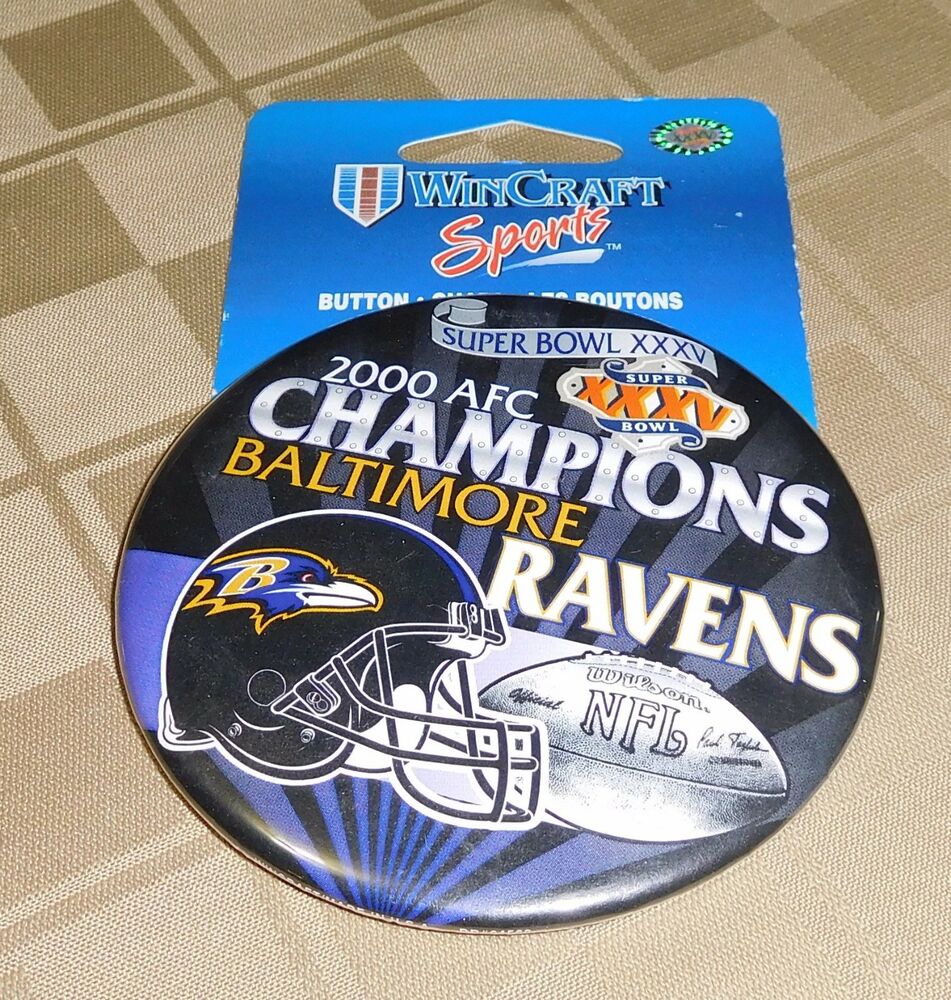

I designed a new approach and sold it to the marketing, engineering, and production staff. My new design reduced the size of the card by more than half. It also completely eliminated the costly blister card heat-sealing step in production.

Since the new card didn’t specify the product size, it also greatly reduced the number of different header cards we needed to keep in stock.

This idea saved thousands of dollars each year. It also greatly reduced the amount of material needed. It used less paper and we no longer needed any plastic blisters.

Efficient packaging examples